Book: Everything about the cult controller

Making Off, historical backgrounds, stories and anecdotes about the "best piano controller in the world" will be published as a book. Including, of course, the collected MK23 FAQs and even more specialist knowledge, musical thoughts and philosophies on the development of new high-end musical instruments.

F. Lachnit has also worked as a journalist and author. He has been a musician for 45 years and is an musical instrument maker, music electronics engineer and owner of his company FLKeys.

Planned publication date approx. 2027.

If you would like to secure a copy today... Reservation and pre-order to:

info

@f

lke

ys.at

Why is a LACHNIT MK more expensive than other keyboards?

Every LACHNIT MK keyboard is built manually and every single key is individually adjusted for evenly smooth moving and finely regulated multiple times. This and several other details are the reasons why our keyboards are so excellent to play. All these delicate work can only be done manually by the most highly trained instrument makers, who deserve to be paid appropriately.

The LACHNIT MK was developed entirely in Austria and is manufactured in Vienna. To keep the price of our keyboards from reaching astronomical heights, we do not include all the development expenses. Expenses were especially incurred by the development of FLK Light Sensor Technology, which took several years.

Is playing a LACHNIT even three times better?

When choosing a musical instrument, you should look beyond the economical, the price, expenses and value, or you would probably never buy any musical instrument. But that would leave so much joy and happiness behind, yours and your audience’s. Not using a bad and unsuitable but common metaphor about cars (Audi – Porsche), it is best explained this way. There are concert grands from mass production and then there are those made by traditional European manufacturers. All of them sound like grands, with nearly the same volume and dynamics but there is still a (little?) difference between them. For some people the difference is not so big and so it is insignificant, for others it makes up the soul of an instrument. To achieve this distinction, to breathe the soul into an instrument, much more effort, experience, craftsmanship and individual attention has to go into every single instrument.

How much is an instrument’s soul worth to you?

How much is the musician’s joy and happiness worth?

4096 High Resolution MIDI ? “Can you even hear 4096 or more different steps of dynamic resolution?”

Any kind of digital stepping is at some point a limitation, dulls the senses faster and quickly leads to boredom.

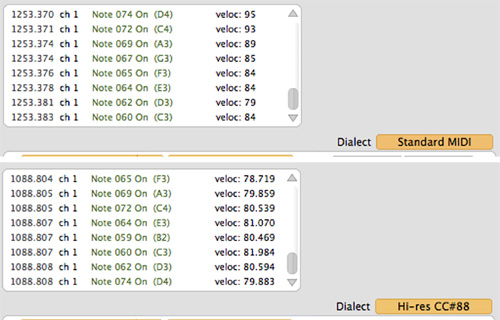

Yes, this might be true: Not even 127 steps can be deliberately played individually. Also it is impossible to consciously distinguish one step out of the 127. But that is not what it is about. The audible steps are limited to 127, so eventually the musician will catch the same step involuntarily. Even though they come in various combinations, the acoustic colours of the individual notes repeat themselves. With our MK Controllers to

"fill" (or to activate) all the MIDI steps from 1 to 127 takes on an average one minute. For example, playing in mezzo forte with medium strike will activate ± 10 MIDI steps. Within these 20 steps the user will involuntarily reach

the same MIDI value many times and consequently produce the same exact sound as before.

In contrast, it is impossible to reproduce the same exact sound on any acoustic instrument, where each new sound is the unique result of interacting "analogue" processes. On a serious level it is therefore impossible but also not desirable to replace a "real" acoustic grand piano. Our goal is to give musicians as much joy in playing with our

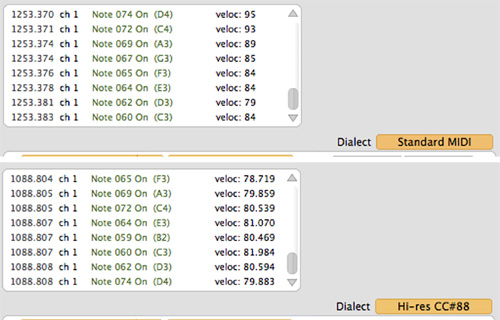

keyboard as they would have with a real high quality instrument.To increase the resolution (to 4096) means that playing in mezzo forte activates about 640 different steps and it takes a lot more time until the exact same sound is produced twice. As a result the sound is livelier and more divers. Held or pedaled chords enrich the overall sound with more overtones and colors. So musicians are able to influence the resulting sound even more and can transfer more of their personal musicality.

Of course it requires adapted sound software. The most promising is the physical modelling technology as it

calculates each sound in real time based on the datas of the measurements taken of the keyboards sensors. For example Pianoteq Version 3.6 or higher is MIDI Hi Res compatible. Other software producers will certainly follow soon.

© FLKeys